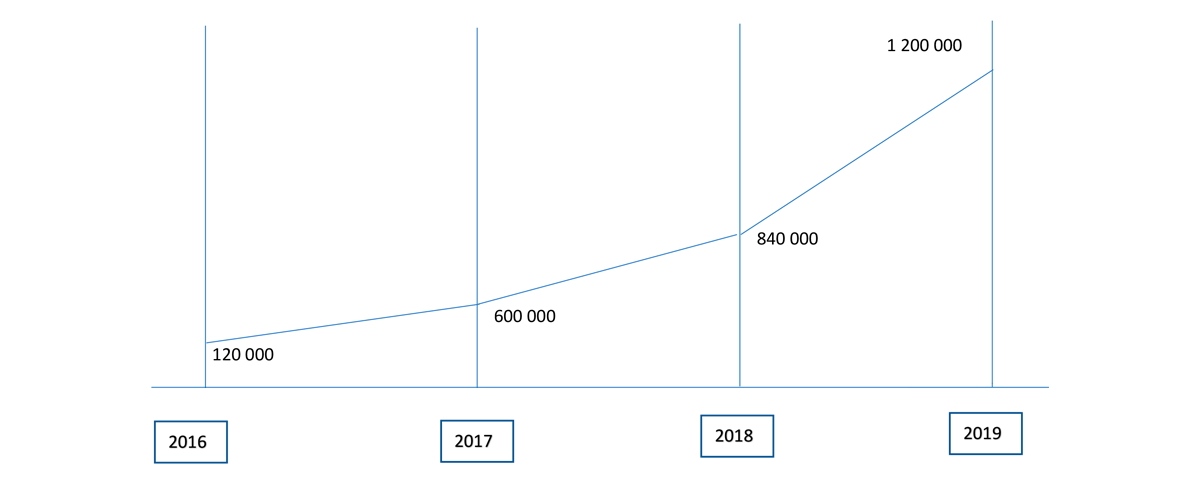

The manufacturing process greatly relies on proper stock management. If the stock control policies are effective, a company can obtain the maximum profit.

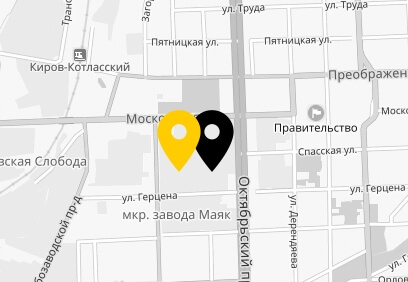

Konstanta is in a position to arrange for additional storage facilities in close proximity to the customer to eliminate the risks associated with delivery failures caused by force majeure circumstances.